THE SPECIFICS

As a truck approaches one four scales at the MRF, a radio frequency identification (RFID) system gathers information from the truck and completes a transaction with a verification from the driver at a kiosk. The fast actuating doors keep sound and odors from emitting outside of the MRF.

Riel Johnson, general manager of the Sun Valley MRF, says the doors help to keep the facility under negative pressure to meet California’s South Coast Air Quality Management District’s Rule 401. The MRF is kept under a negative pressure by utilizing ceiling mounted fans that pull fresh air into the building and exhausting the air through a halo of high-pressure sprayers that neutralize any odors.

Once the trucks are inside, they back up and unload mixed waste onto the tipping floor, where loads are separated with a quick visual quality inspection. The materials coming into the facility are a combination of commercial mixed waste and multifamily loads containing a little bit of everything. “You name it,” Johnson says, and the MRF has probably seen it. The MRF receives about 130 truckloads of materials daily.

Loads deemed of good quality are placed to one side of the facility, while loads of poor are moved to the other side. Athens uses a Caterpillar M322D MH material handler equipped with a rotating Rotobec trash grapple to move material on the tip floor.

“This has done a great job of doing a lot of presorting for us and taking out the bed frames, tires and couches and various other things that could end up on the system,” Johnson says. Another benefit of the material handler, he says, is that it acts as a metering tool. The processing line also is equipped with a metering device to help keep the system running at a steady rate and material thickness.

MECHANICAL SEPARATION

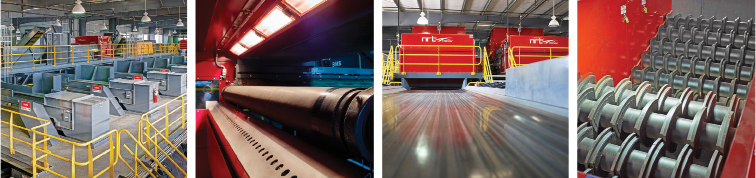

The 70-ton-per-hour (TPH) mixed-waste MRF was designed, engineered, manufactured and installed by Eugene, Oregon-based Bulk Handling Systems (BHS). Among the equipment used to separate commodities from the waste stream is a BHS disc screen, Nihot air separation equipment and NRT optical sorting technology.

The processing line starts with the presort. Large pieces of metal, plastic and wood are pulled out at this stage. In addition, the multifamily loads typically consist of bagged waste that Johnson describes as “containing lots of good stuff.”

A BHS bag breaker rips open the bags, liberating the waste inside. The bags’ contents are conveyed back onto the system. Johnson says Athens recycles about 6 tons per day of plastic film.

The remaining material is conveyed into a large opening. The OCC (old corrugated container) separator scalps off OCC. Other materials fall onto a debris roll screen, which removes organic fines and glass. Nihot air technology separates material by density, and a BHS polishing screen separates containers from paper and plastic bags. At this stage, light materials are separated into paper, containers and plastic bags. A FiberPure screen removes small, wet pieces of paper.

The system contains six stacked optical sorters. Two optical sorters separate fiber from film. The remaining optical sorters separate plastics by type: polypropylene (PP), high-density polyethylene (HDPE), polyethylene terephthalate (PET) and mixed plastics Nos. 3-7. Ferrous metals are removed using a magnet, while an eddy current separator removes nonferrous metals.

Each separated commodity then falls into a product bunker, where it is baled and ready to be shipped. The MRF employs 130 people, and Johnson says Athens tries to hire local workers to fill these positions. The MRF currently is processing 1,200 to 1,300 tons per day (TPD) on two shifts. It is permitted to process 1,500 TPD.

FINDING OPPORTUNITIES

In addition to the various plastics grades, Athens also separates mixed paper, magazines (OMG), OCC, aluminum cans, aluminum foil, steel, aseptic containers and California Refund Value (CRV) glass.

According to Johnson, Athens always is eager to do more with the materials that come into the facility. “We are always looking for opportunities,” he says. That includes considering shredding a fraction of the MRF residual to produce a refuse-derived fuel (RDF).

While the company is not yet producing an RDF product at the facility, Johnson notes, it is looking at equipment to produce a high-quality RDF, including an optical sorter to sort out PVC and any valuable containers that may have been missed during processing. And that is not all. “We are spending a lot of effort on researching technology to process organics,” Johnson adds.

Mixed waste offers flexibility that single-stream MRFS do not have, according to Johnson. “Mixed waste processing is an enabler,” Johnson says. “It allows us to break open the waste pile and see what’s in there. By doing this, we are able to find opportunities to utilize the waste as a resource. Whether it be as a fuel or another emerging market. It’s easier on the customer—no decisions to make; just put it in a can we take it from there.”

Mixed waste offers flexibility that single-stream MRFS do not have, according to Johnson. “Mixed waste processing is an enabler,” Johnson says. “It allows us to break open the waste pile and see what’s in there. By doing this, we are able to find opportunities to utilize the waste as a resource. Whether it be as a fuel or another emerging market. It’s easier on the customer—no decisions to make; just put it in a can we take it from there.”

Another added benefit to processing everything in one place, Johnson points out, are that fewer trucks are out on the streets.

Athens Services has been providing waste collection and recycling services in Southern California for since 1957. In addition to the MRFs it owns and operates, the company provides waste and recycling collection, green waste recycling, food waste/organics collection and composting, commercial bin and compactor services, construction and demolition services, special waste transportation, transfer and material recovery, storage box rentals and street/parking lot sweeping.

Athens Services has been providing waste collection and recycling services in Southern California for since 1957. In addition to the MRFs it owns and operates, the company provides waste and recycling collection, green waste recycling, food waste/organics collection and composting, commercial bin and compactor services, construction and demolition services, special waste transportation, transfer and material recovery, storage box rentals and street/parking lot sweeping.

The company’s website states, “As owners and operators of multiple MRFs, a composting facility, plus operation and management of the San Bernardino Landfill system, Athens Services offers the highest diversion waste and recycling programs for residential, commercial and municipal locations.”

Loughnane says, “Athens’ growth in the region is testament to the city’s commitment to achieve zero waste. We don’t own any landfills. Our focus has always been exclusively on responsible waste collection and investing in the newest technologies to recover as much material as possible for other uses.”

By investing in technology and hiring locally, Athens’ commitment to the communities it serves is evident. Athens says it currently maintains the largest recycling infrastructure of any company operating in the Southern California market.

By investing in technology and hiring locally, Athens’ commitment to the communities it serves is evident. Athens says it currently maintains the largest recycling infrastructure of any company operating in the Southern California market.

Its Sun Valley MRF gives Athens a recycling processing capacity of 2 million tons per year of MSW, continuing its commitment, the company says, to build the largest municipal solid waste management infrastructure in the greater Los Angeles area.

The fully enclosed facility’s modern features also include a built-in system to mitigate dust and odors to comply with air quality requirements.

The fully enclosed facility’s modern features also include a built-in system to mitigate dust and odors to comply with air quality requirements. Recent Award

Recent Award

In the News

In the News

Video Spotlight

Video Spotlight